RF Heating Lines

Traditional Thawing lines depend on conventional heating that uses either steam or electrical heaters that are inefficient and take a long residence time to heat. This results in an uneven thawing profile as well as build-up of microbial load.

Over the past couple of decades, Radio Frequency heating has taken a front step in solving this problem because, unlike traditional heating which involves heat being transferred from the outside(case) of the product to the core, RF heating generates heating within the product.

This allows for an even thawing profile and an accelerated process time for thawing since there is no longer a dependency on the inconsistent thermal properties of the product to dictate the thawing time.

Additional advantages include the reduction in drip losses due to the even thawing of the product as well as a significant drop in pathogenic load due to the reduced process time.

While principles of the technology stay the same, RF technology does seem to have drawbacks that show over time. Specifically, the heating of the product is dependent on its electromagnetic properties which change depending on the temperature, fat content, and water content.

While two instances of the same product can never be identical, technology disadvantages exponentially amplify when standard high-energy density RF fields are applied for thawing.

This poses a problem when dealing with large-scale production volumes when inconsistencies get out of hand. Secondly, as regulation and ESG standards around industrial processes are now tightly monitored, RF manufacturers are facing a challenge in designing equipment that is truly CE and CISPR 11 compliant.

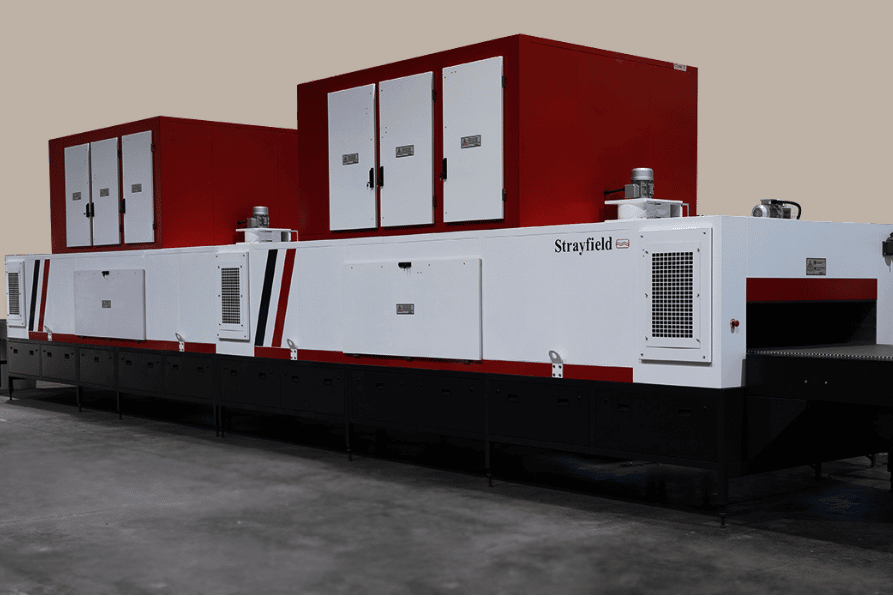

Strayfield has recently solved these problems by developing proprietary low-energy density RF field equipment which is truly CE and CISPR 11 compliant. This design can meet production standards while handling a spread in input characteristics.