An Efficient and Safer Alternative for Disinfestation & Pasteurization for the European Food Industry

The quest for safe and effective sterilization and disinfestation methods for the food industry has taken center stage, particularly due to the European Union’s (EU) ban on Ethylene Oxide (ETO). With the need for a viable alternative, Strayfield’s Radio Frequency Dryers have emerged as strong contenders. This article explores how our innovative devices can revolutionize the EU food industry and why they are worth the investment.

Strayfield’s Radio Frequency Heaters– The Future of Disinfestation

Strayfield, a leading name in the field of industrial heating & drying solutions, has developed a range of Radio Frequency (RF) equipment designed specifically for disinfestation. The RF technology uses radio frequency energy to generate heat, effectively killing pests and pathogens in food without leaving any chemical residues or the risks associated with chemical sterilization methods like ETO

Convincing Reasons for Choosing RF Dryers

Elevate Your Knowledge: European Food Industry

Safety

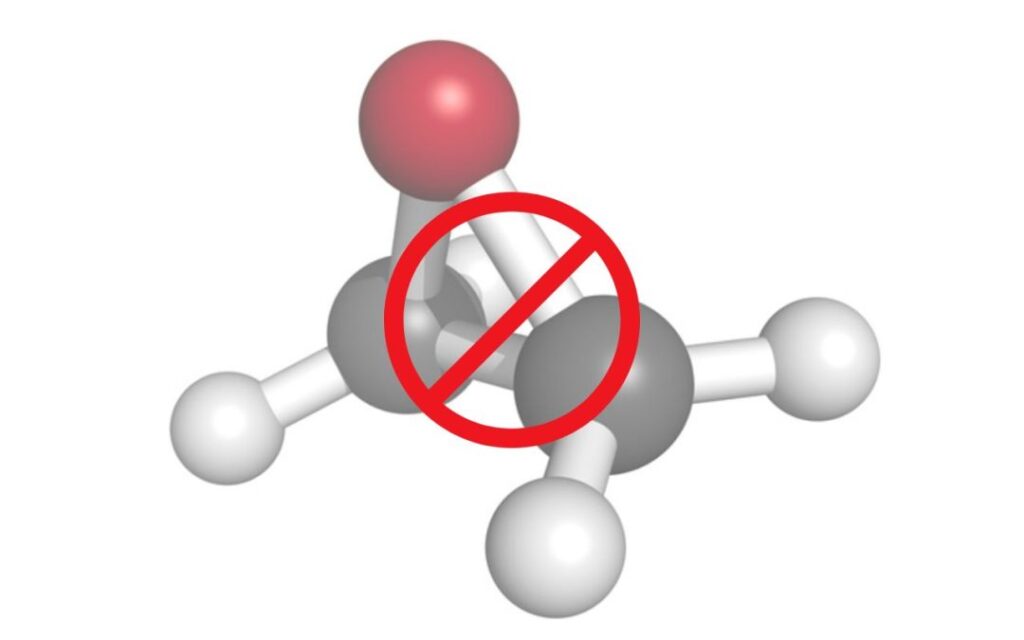

Unlike Ethylene Oxide (ETO) treatment, radio frequency (RF) treatment does not rely on potentially harmful chemicals. ETO is a gas that is commonly used for sterilizing and decontaminating various products, including food. However, ETO has been associated with health concerns and regulatory restrictions due to its toxic and carcinogenic properties. In contrast, RF treatment offers a chemical-free alternative for ensuring the safety of food products.

RF treatment utilizes high-frequency electromagnetic energy in the radio frequency range to heat food. This heating process effectively eliminates or reduces the presence of pathogens, bacteria, and other microorganisms that may be present on the food surface or in its internal structure. The heat generated by RF treatment is sufficient to destroy harmful microorganisms, ensuring that the food is safe for consumption.

Another significant advantages of RF heating is that it operates within the non-ionizing spectrum of radiant energy. Unlike ionizing radiation, such as gamma ray treatment, which has sufficient energy to remove electrons from atoms and potentially cause cellular damage, RF energy does not have this ionizing effect. As a result, RF treatment poses a lower risk of causing biological harm compared to ionizing radiation-based methods like gamma ray treatment.

By using RF heating, food products can be treated to enhance their safety and shelf life without leaving behind any chemical residues or introducing potential health risks associated with ionizing radiation. This makes RF treatment a safer technology for use in food processing and preservation, as it offers a non-toxic and non-ionizing approach to ensure the microbiological safety of food.

Efficiency

RF equipment by Strayfield is particularly effective at uniformly heating and drying the product, thereby ensuring the complete eradication of pests and pathogens without damaging the food grains or ingredients. This is a significant advantage over traditional heating methods, which can leave cold spots where pests can survive.

Maintaining Quality

RF Heaters do not alter the nutritional content, taste, or appearance of food grains. This is a crucial factor considering the EU consumers increasing demand for food products that retain their natural properties.

Environmental Impact

RF Heaters are an environmentally friendly option. They do not emit harmful substances into the environment, aligning with the EU’s robust environmental policies and objectives.

Cost-Effectiveness

While the initial investment in RF technology might seem high, the long-term cost efficiency becomes apparent when considering reduced wastage, lower energy usage, and minimal maintenance requirements.

Implications for the European Food Industry

Beyond Borders: The European Food Industry Unveiled

Investing in RF equipment by Strayfield could fundamentally transform the European food industry. Firstly, it would help the industry align with the EU’s safety regulations by providing an efficient, residue-free disinfestation/pasteurization method. This would enhance consumer confidence in the safety and integrity of food products, bolstering market demand.

Secondly, the use of RF Heaters can boost operational efficiency. The speed and uniformity of RF processing can reduce processing times, allowing for increased throughput. Moreover, these systems can be easily integrated into existing processing lines, minimizing disruption during implementation.

Finally, with sustainability being a top priority in the European Union, the switch to RF Pasteurizing equipment could significantly enhance a company’s credentials. This could translate to a stronger market position and potentially access to incentives or benefits linked to sustainable practices.

Conclusion

The EU’s ban on ETO necessitates a shift towards safer, more sustainable disinfestation or stabilizing methods. Strayfield’s Radio Frequency equipment offer an innovative and highly effective solution that aligns with the needs and values of the European food industry. By investing in RF technology, European companies can ensure safety, efficiency, quality preservation, environmental sustainability, and long-term cost-effectiveness – a combination that convincingly argues for this transformative technology.