A Comprehensive Case Study:

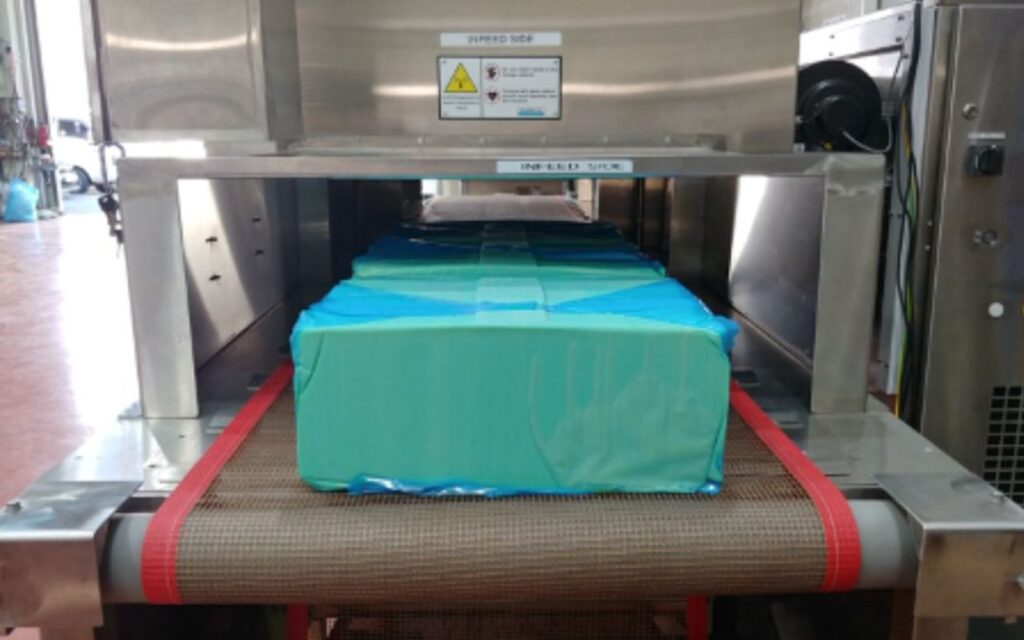

The food industry is constantly seeking innovative solutions. One such advancement is the Radio Frequency (RF) defrosting method, a technology that promises quick thawing while maintaining the integrity of food products. Our case study focused on assessing the capabilities of an RF defrosting/tempering unit from Strayfield, using butter as the test product.

Customer Requirements:

- Product: Butter

- Dimension: 350mm x 275mm x 140mm

- Weight: 12.5kg

- Desired Temperature Change: From -18℃ to above 0℃, with the aim to keep the butter’s rectangular parallelepiped shape.

- Initial Temperature: The butter samples predominantly began at around -13℃.

A Comprehensive Case Study:

The food industry is constantly seeking innovative solutions. One such advancement is the Radio Frequency (RF) defrosting method, a technology that promises quick thawing while maintaining the integrity of food products. Our case study focused on assessing the capabilities of an RF defrosting/tempering unit from Strayfield, using butter as the test product.

Customer Assessment:

The client recognized the RF defrosting unit’s potential to efficiently bring the butter to room temperature. This offers immense value to industries that require rapid tempering processes without affecting the product quality.

The client also acknowledged the consistency of the product after testing and is keen on exploring the technology further through secondary testing.

Conclusion:

The Strayfield RF defrosting/tempering unit has showcased its potential in the rapid defrosting of butter. With its promising results, it’s evident that with further collaboration and refinement, this technology can become a valuable asset in the food industry.