In the realm of electromagnetic heating technologies, Microwave and Radio Frequency (RF) heating stands out for its distinctive characteristics and applications. Although both methods utilize electromagnetic energy to generate heat, understanding their differences is pivotal for selecting the appropriate technology. This blog aims to highlight the key distinctions between Microwave and Radio Frequency heating without delving into overly technical language. Additionally, it includes an appendix that provides more specific technical details without resorting to intricate mathematical equations.

The Basics of Electromagnetic Heating

Electromagnetic heating harnesses electromagnetic energy to heat materials. This energy, operating at various frequencies, interacts with certain materials, causing the molecules within those materials to vibrate and generate heat. Both Microwave and Radio Frequency heating, commonly known as dielectric heating or volumetric heating, operate on this principle, albeit at different frequencies within the electromagnetic spectrum.

Microwave Heating

Microwave heating operates within a frequency range of approximately 950 MHz to 2450 MHz, with the most prevalent application at 2450 MHz. The higher frequency of microwaves enables the rapid heating of materials. This is because microwaves excite a variety of molecules in these substances, inducing rapid vibration and heat generation.

Microwave heating is commonly used for cooking but also find applications in processes such as drying, curing, sintering, and chemical synthesis. The primary advantage of microwave heating lies in its speed and efficiency in uniformly heating small-sized volumes of material. However, due to their short wavelength, microwaves are limited to applications on products with proportionally small dimensions.

Radio Frequency Heating

Radio Frequency heating operates at frequencies lower than microwaves, typically between 13.56 MHz and 40.68 MHz, with 27.12 MHz being the most common industrial frequency in the heating context. RF heating proves particularly effective for heating & drying large to medium-sized volumes of material or for materials that are less receptive to microwave energy.

One of the key advantages of RF heating is its ability to evenly heat larger materials throughout their volume. This is particularly advantageous for processes requiring uniform heating, such as defrosting and tempering frozen food, drying wood or textiles, and vulcanizing rubber. Unlike microwave heating, RF heating can penetrate deeper into materials, providing more uniform internal heating.

Key Differences

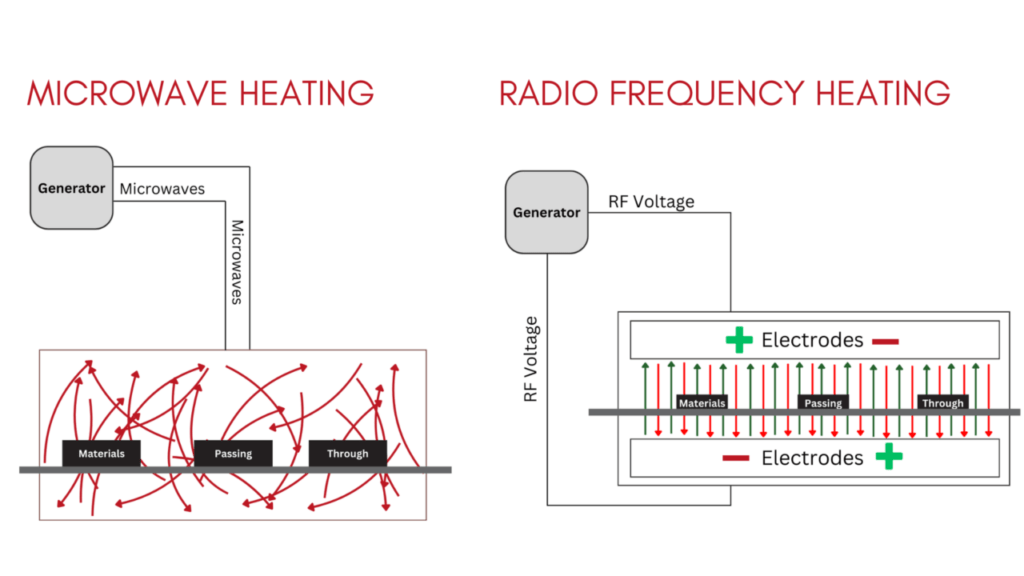

The primary difference between Microwave and Radio Frequency heating lies in their frequency ranges, directly impacting their heating mechanisms and applications. Microwave heating is better suited for the rapid heating of volumetrically smaller masses that are good absorbers of microwave energy. Conversely, RF heating is ideal for the uniform heating of larger volumes.

Higher Penetration Depth: RF heating, due to its longer wavelength, penetrates deeply even into dense and large materials, making it suitable for products of various sizes.

Better Heating Uniformity: RF energy is delivered through an applicator designed according to the product and process constraints/geometry, ensuring even energy absorption and reducing the risk of uneven temperature distribution. Microwave energy, on the other hand, often causes uneven heating due to wave interference patterns.

Higher Selectivity: RF heating is more selective due to the larger differences in loss factors of water and other organic and non-organic materials at lower frequencies, allowing for targeted drying processes without affecting the properties of the final product due to excessive exposure to heat.

Both Microwave and Radio Frequency heating technologies offer unique advantages depending on the application. Understanding their differences is essential for selecting the most appropriate method for specific heating needs. Whether it’s for the rapid heating of materials or the uniform heating and drying of materials in an industrial setup, choosing the right electromagnetic or volumetric heating technology can significantly impact efficiency and qualitative outcomes.

Appendix

Insights into the Differences Between RF and Microwave Heating

The disparities between Radio Frequency (RF) and Microwave heating can be understood better by exploring the underlying technical principles governing their interactions with materials. These interactions are influenced by several factors, including the dielectric properties of the materials, the relationship between penetration depth of the electromagnetic energy and the operating frequency, and the frequency-dependent behaviour of the heating process.

Dielectric Properties

Dielectric Loss Factor: The dielectric loss factor indicates how efficiently the material can convert electromagnetic energy into heat. Materials with a high loss factor heat more effectively under the influence of oscillating electromagnetic fields. Microwave heating, operating at higher frequencies, tends to be more efficient for materials with high water content due to water’s significant loss factor at these frequencies. In contrast, RF heating can efficiently heat a broader range of materials, including those with lower water content (e.g. cookies & baked goods, post-baking), because the frequencies at which RF operates allows for interactions with a wider variety of molecular structures and materials compared to the higher frequencies used in microwave heating.

The interaction between electromagnetic energy and the material’s molecular structure is frequency-dependent. Microwaves are particularly effective at agitating dipolar molecules, like water, leading to rapid heating. RF heating, while still capable of agitating molecules, is less selective and can heat a wider variety of materials by inducing ionic conduction and dipole rotation throughout the material due to the circuit configurations employed.

Uniformity of Heating: Differences in operating frequency affect heating uniformity. Microwave heating can sometimes cause uneven heating due to wave interference patterns, resulting in hotspots. RF heating, with its longer wavelengths and deeper penetration, tends to provide more uniform heating across the volume of the material, reducing the risk of uneven temperature distribution.

Moreover, when electromagnetic energy passes through a material, it can be absorbed and converted into heat. This process is associated with the material’s dielectric properties, specifically the dielectric loss, which generally tends to decrease (though not always) as the frequency of the electromagnetic wave decreases. Lower-frequency (longer wavelength) energy, in general, is absorbed less as it passes through the material and thus can penetrate deeper into the material before its energy is significantly diminished.

Some materials, like water under sub-zero conditions in the state of ice, are virtually transparent to microwaves (or have minimal energy absorption capability) but can absorb much lower RF frequencies. Conversely, some materials, like certain grades of ceramic materials, are transparent to RF frequencies but will heat up, to even sinter, with microwaves.

To gain further insight into which technology is best suited for your needs, or to acquire an in-depth understanding of the technology, please visit us at www.mongagroup.com or contact us at sales@mongagroup.com.