Rapid Defrosting for 10kg and 20kg Surimi Blocks Using Strayfield’s RF Seafood Defroster.

In the area of food processing, efficiency, quality, and optimal use of space are paramount. At Strayfield, we are committed to pioneering solutions that meet the ever-evolving needs of this industry. We are excited to release a case study on the RF defrosting of 10kg and 20kg Surimi blocks.

The Challenge of Tempering Surimi

Surimi, a versatile fish paste used in a variety of applications, requires careful handling to maintain its texture and flavour. Traditionally, defrosting Surimi blocks has been a time-consuming process that can affect product quality. Slow defrosting methods often lead to uneven temperature distribution, prolonged defrosting times, increased bacterial load, and, in some cases, drip losses.

Our Innovative Solution

Our advanced defrosting technology addresses these challenges head-on, providing a fast, efficient, and uniform defrosting process for Surimi blocks. Here’s how our solution stands out:

- Precision Temperature Control: Our technology ensures even heat distribution throughout the Surimi block, preventing hotspots and maintaining a maximum temperature differential of 1℃ across the block.

- Reduced space, increased speed, and increased efficiency: Designed to minimise defrosting times significantly, our system ensures that the entire block is brought to -1.5℃ in just 15 minutes within a conveyorized tunnel design, eliminating the need for large defrosting rooms. This means you can get more products to market faster without compromising on quality.

- Maintaining Quality and Safety: By using our technology, Surimi blocks are defrosted in their original packaging, reducing the risk of contamination and ensuring product safety. Additionally, due to the reduced defrosting time and the temperature of the entire block remaining below 0 ℃, there is minimal bacterial load buildup.

Customer Requirements

To ensure our defrosting machine meets the needs of our clients, we consider several key customer requirements:

- Product Compatibility: Our system is designed to accommodate both 10kg and 20kg(double stacked 10 kg blocks) Surimi blocks, providing flexibility to suit various processing needs.

- Ease of Integration: Our technology seamlessly integrates with existing production lines, minimising disruption and allowing for a smooth transition.

- User-Friendly Operation: We prioritise simplicity and ease of use, enabling operators to quickly master the system and maintain high levels of productivity.

- Customizable Settings: Understanding that different products may require unique handling, our technology allows for customizable settings to optimise defrosting for various Surimi formulations.

Test Product

Product: Surimi Blocks

Weight: 10 kg per block

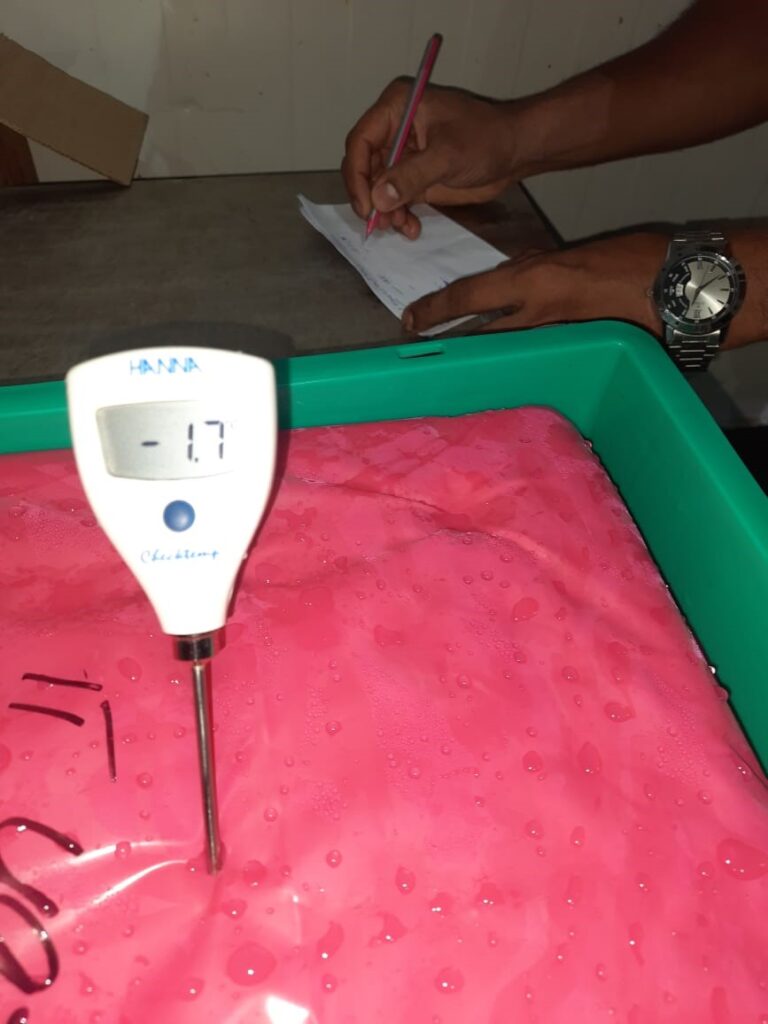

Desired Temperature Change: Tempering Surimi blocks from -18℃ to above -1.5℃, to keep the block’s temperature variation under 1℃.

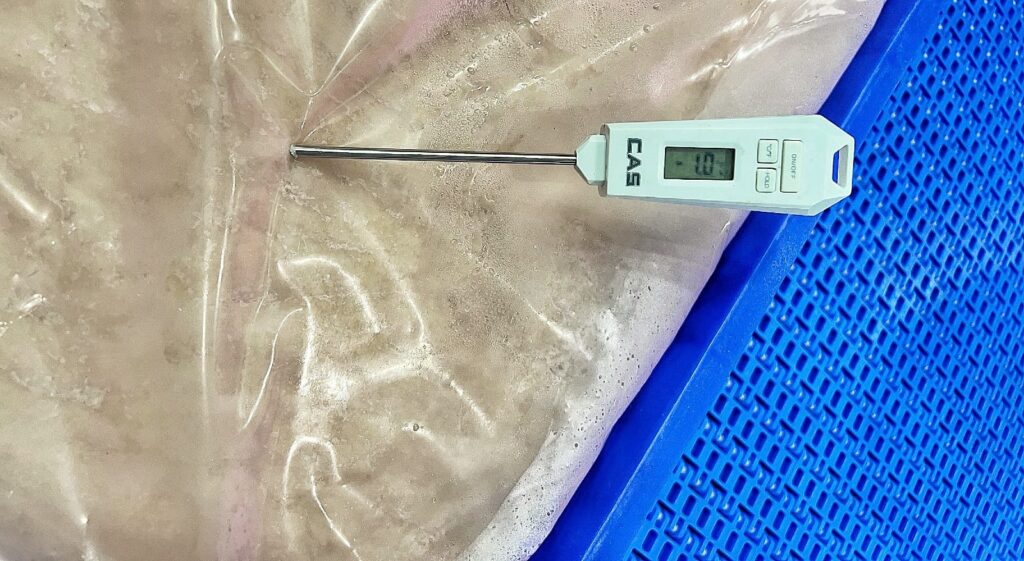

Initial Temperature: The Surimi samples predominantly began at around -17℃.

Why Choose Strayfield?

At Strayfield, innovation is at the heart of what we do. Our defrosting technology for Surimi blocks exemplifies our commitment to delivering state-of-the-art solutions that empower your business. We understand the unique challenges faced by the food processing industry, and we are dedicated to providing technologies that drive success.

- Experience and Expertise: With a proven track record in RF defrosting technologies, we bring expertise and innovation to every project.

- Commitment to Quality: Our technology is rigorously tested to ensure it meets the highest standards of performance and reliability.

- Customer Support: We offer comprehensive support services to assist with installation, training, and ongoing maintenance.