Revolutionizing the Drying Process in Ceramics and Fiberglass with Strayfield’s Radio Frequency (RF) Technology

The ceramics and fibreglass industries have long struggled with drying processes that consume time, energy, and resources. Conventionally, drying these materials using batch ovens can take up to 12 hours or more, leading to inefficiencies and elevated costs. Enter Radio Frequency (RF) technology—a game-changer that promises faster drying times, lower energy consumption, and enhanced product quality.

The Challenges of Conventional Drying

Drying ceramics and fibreglass is notoriously difficult due to their low thermal conductivity. After drying the surface using conventional methods, moisture removal from the inner sections slows dramatically, which often leads to issues like cracking in ceramics or uneven binder distribution in fibreglass. This is where RF drying comes in. Unlike traditional convection ovens, which heat from the outside in, RF technology uses dielectric heating, a process that uniformly heats the entire material by exciting water molecules.

Why RF Drying Works

Strayfield’s RF technology targets the moisture within the material, directly heating the water molecules. This results in quicker, more even drying across the entire product. For instance, drying time for ceramics can be reduced from 12 hours to just 30 minutes, while fibreglass strands or rovings can be dried in 90 minutes compared to the usual 24 hours.

The key advantage here is that Strayfield RF drying prevents the overheating of the material itself, thus reducing thermal stresses that could lead to cracks or defects. The process is also energy-efficient because the heating is directed at the water, not the material or the oven structure. This eliminates waste heat and improves overall energy efficiency.

Solving Conventional Oven Issues

One of the significant drawbacks of conventional batch ovens is that they require long warm-up and cool-down times, and their inefficiency is compounded by energy loss. Additionally, batch ovens tend to process products inconsistently, resulting in wasted time and materials.

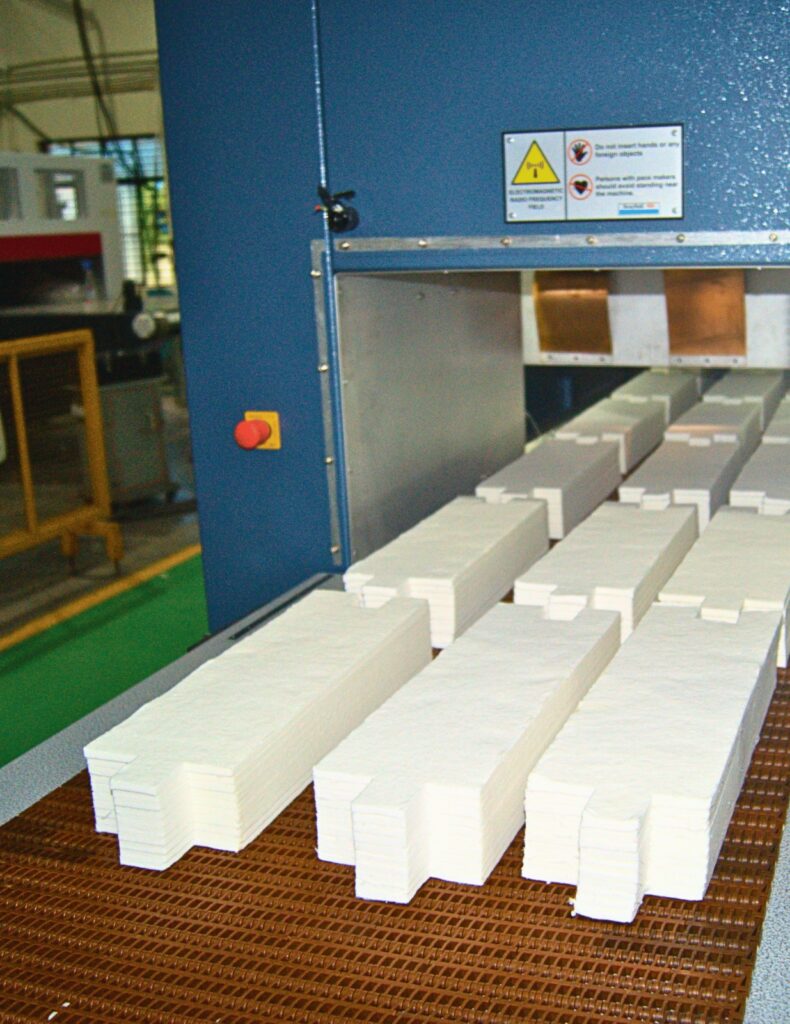

Strayfield’s RF technology addresses these challenges by incorporating a continuous conveyor system that feeds materials through the drying process without interruptions, with a startup time of only 1-2 minutes. This not only accelerates production but also ensures more efficient energy usage As a result, manufacturers experience reduced drying times, energy costs, and defects in finished products.

The Green Factor

In today’s environmentally conscious world, energy efficiency and electrification are top priorities for manufacturers. Our RF drying solutions offer a cost-effective and fully electric operation. Since the energy is absorbed by the water within the material rather than the oven or the material itself, less energy is required, making it a more sustainable alternative to conventional drying methods. By optimizing energy consumption, RF technology helps companies achieve their sustainability goals while also reducing operational costs.

Conclusion

RF drying is revolutionizing the ceramics and fiberglass industries by offering a more efficient, cost-effective, and environmentally friendly way to dry materials. By drastically reducing drying times and improving product quality, RF technology is poised to become a standard in these industries where inefficient moisture removal is currently a significant bottleneck.

As manufacturers seek sustainable and efficient technologies, Strayfield provides an innovative drying solution that enhances productivity while supporting environmental goals. Our RF technology is ideal for drying ceramic fiber boards, ceramic fiber shapes, ceramic blankets, fiberglass strands, fiberglass rovings, basalt fiber rovings, and other thermally insulating high-temperature materials, offering both efficiency and eco-friendliness.

Reference

Blaker, G. and Glenn Blaker is Technical Director at PSC Inc. (2015) Radio frequency drying of ceramics and fiberglass, Ceramic Industry RSS. Available at: https://www.ceramicindustry.com/articles/94541-radio-frequency-drying-of-ceramics-and-fiberglass/

Contact us to know more