Formation, Risk, and Why It Is So Hard to Control

Acrylamide remains one of the most persistent food safety challenges in baked goods. It forms naturally during baking in carbohydrate rich products such as biscuits, crackers, wafers, breads, and cereals. The challenge lies in the fact that acrylamide is generated by the same chemical reactions that create desirable colour, flavour, and aroma.

Regulators require manufacturers to actively mitigate acrylamide formation, yet any mitigation strategy must preserve sensory quality and consumer acceptance.

What Is Acrylamide and Why It Forms

Acrylamide is a process induced chemical contaminant formed during high temperature cooking. From a toxicological perspective, it is classified as a potential carcinogen. This has led regulatory bodies, including the European Union, to mandate mitigation strategies across multiple food categories.

A key challenge is that acrylamide is not added externally. It forms inside the product matrix during baking itself. Eliminating it completely would require eliminating browning, which is not commercially or sensorially viable.

The Role of the Maillard Reaction

The Maillard reaction is a complex series of reactions between reducing sugars such as glucose and fructose and amino acids, primarily asparagine. It begins at moderate temperatures and accelerates rapidly above approximately 120 °C, especially under low moisture conditions.

This reaction is essential for baked goods because it drives:

- Browning and surface colour

- Flavour development

- Aroma formation

Acrylamide forms as an unintended product of this same reaction when conditions of high temperature and low moisture coincide.

The Real Issue: HarmWhy Conventional Baking Increases Risk onics, Not the Fundamental

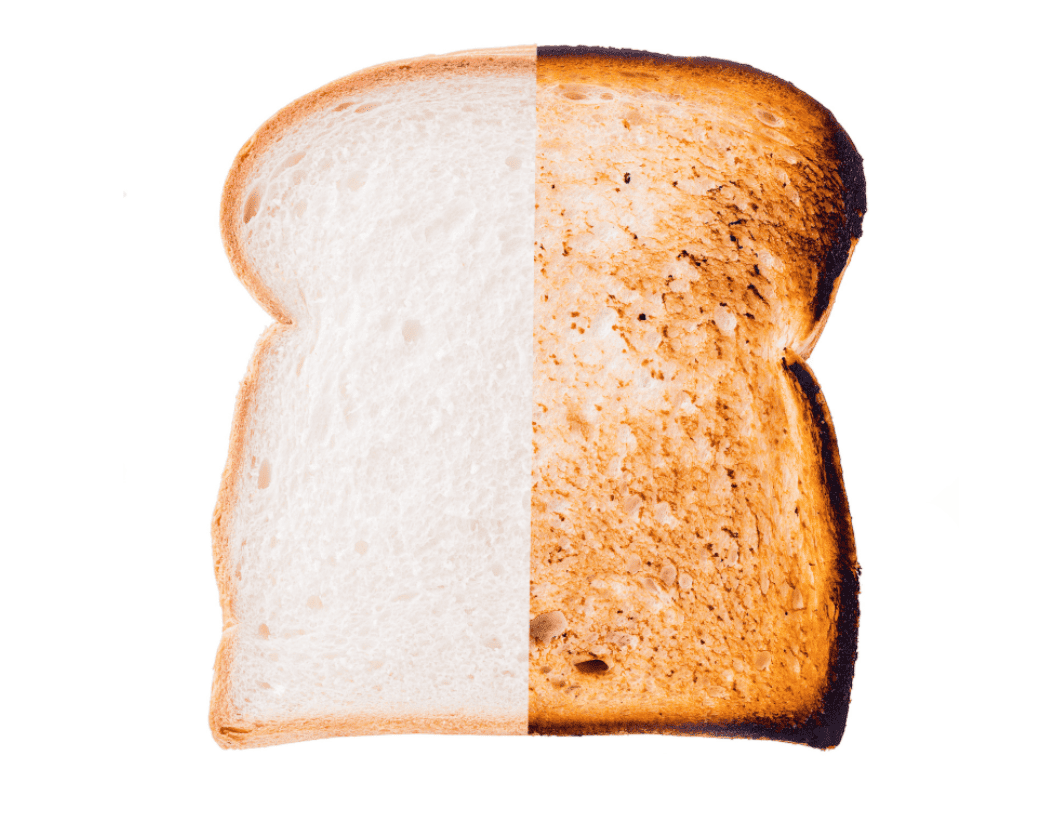

In conventional hot air baking, heat transfer occurs from the surface inward. Surface moisture is lost first, while internal moisture migrates outward more slowly. As a result:

- Drying and browning occur simultaneously

- Longer bake times are needed to reach target moisture

- Products spend extended time in hot, dry conditions

These are precisely the conditions that favour acrylamide formation. This creates a direct trade-off between moisture, texture, colour, and food safety.

Regulatory Context: EU Commission Regulation 2017/2158

Commission Regulation (EU) 2017/2158 establishes benchmark levels and mandatory mitigation measures for acrylamide in foods sold within the EU. For fine bakery wares such as biscuits and wafers, benchmark levels are typically around 350 µg/kg.

The regulation requires manufacturers to:

- Reduce acrylamide to as low as reasonably achievable

- Implement demonstrable, process-based mitigation measures

- Monitor and verify results

Importantly, the regulation does not prescribe a single technology. It encourages the use of best available practices that reduce acrylamide while maintaining quality.

Why Process Design Matters More Than Ingredients Alone

Over the years, acrylamide mitigation efforts have focused heavily on recipe level interventions such as raw material selection, enzyme addition, and formulation adjustments. While these approaches can contribute to reduction, they often come with trade-offs in flavour development, texture, or production flexibility.

What the underlying chemistry and regulatory guidance make clear is that acrylamide formation is not driven by ingredients alone. It is strongly governed by process conditions

specifically how long a product is exposed to high temperature once moisture levels fall below critical thresholds.

This shifts the mitigation conversation from what is baked to how it is baked and dried.

By rethinking when and where moisture is removed, manufacturers gain a powerful lever to reduce acrylamide formation without sacrificing the sensory attributes that define baked goods. Scientific evidence increasingly supports the view that separating colour development from final moisture reduction is one of the most effective ways to address acrylamide at its root.

The challenge, however, lies in translating this scientific understanding into a process that works reliably at industrial scale.

What Published Research Confirms About Moisture Control and Acrylamide Reduction

Scientific research consistently shows that acrylamide formation in baked goods is strongly linked to the duration for which products remain under low moisture and high temperature conditions. Controlling how and when moisture is removed is therefore one of the most effective mitigation levers available to food manufacturers.

This understanding has led researchers to investigate post bake drying approaches that enable moisture reduction without extending oven exposure.

Peer reviewed studies referenced in this work demonstrate that acrylamide mitigation is most effective when process conditions are addressed directly, particularly the interaction between temperature, moisture, and time during the final stages of baking.

Key findings from published research include:

- Acrylamide formation increases significantly once surface moisture has been largely removed while product temperatures remain elevated, confirming that exposure time under low moisture conditions is a dominant driver of acrylamide generation via the Maillard reaction.

- In conventional hot air baking, final moisture targets can only be achieved by extending oven residence time after browning has already occurred, inherently prolonging exposure to acrylamide forming conditions

- Experimental studies evaluating RF post bake drying at 27.12 MHz demonstrate that final moisture reduction can be achieved outside the oven, without extending high temperature exposure.

- In controlled experiments on cookies, researchers reported that:

- Fully baked control samples contained approximately 107.3 ng/g of acrylamide

- Samples baked for a shorter duration and subsequently dried using RF contained approximately 51.1 ng/g and 74.6 ng/g of acrylamide, depending on bake severity

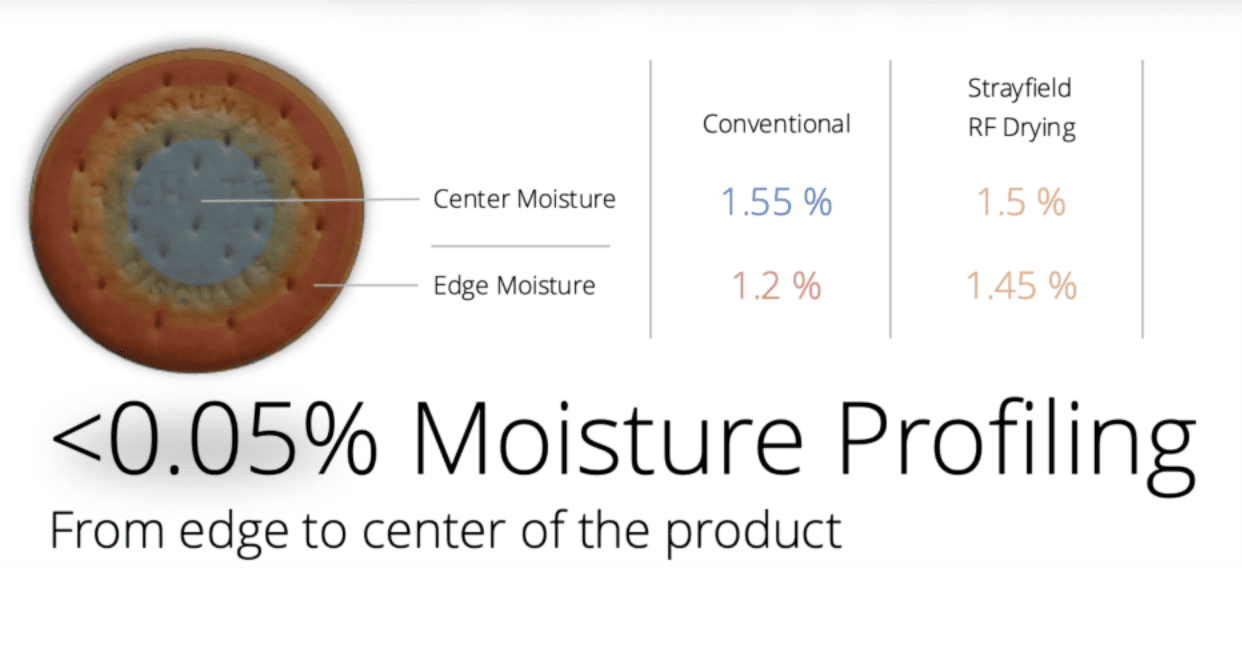

- Final moisture content and texture were comparable between conventionally baked and RF post dried samples, with lighter and more controlled surface browning

- These results correspond to an overall acrylamide reduction of approximately 30 to 50 percent, achieved without under baking or compromising product quality.

- Additional published research, including work by Kocadağlı et al., demonstrated that combining reduced or lower temperature baking with a short RF post bake drying step can reduce acrylamide levels by up to 50 percent compared to conventional baking protocols.

- Review papers on acrylamide mitigation technologies cite RF drying among alternative processing approaches that lower acrylamide formation by altering heat and moisture dynamics, rather than relying on formulation changes alone.

- Across these studies, RF post bake drying is identified as effective because it:

- Enables rapid moisture removal without extending thermal exposure

- Limits the time products spend in low moisture and high temperature conditions

- Reduces further Maillard reaction progression once target colour and structure are achieved

- This process-based approach aligns closely with the mitigation framework outlined in EU Commission Regulation (EU) 2017/2158, which emphasises demonstrable, verifiable processing controls and the application of best available practices that preserve food quality.

Closing Perspective

Taken together, published research confirms that separating final moisture removal from surface browning is one of the most effective ways to reduce acrylamide formation in baked goods. RF post bake drying provides a scientifically validated method for achieving this separation while preserving moisture, texture, and sensory quality.

Industrial RF systems, such as those developed by Strayfield, are engineered to apply these research backed principles in a controlled and repeatable manner, enabling manufacturers to translate laboratory results into reliable, production scale acrylamide mitigation. The following article examines how this is implemented in practice.

References

- European Commission. Commission Regulation (EU) 2017/2158

- Kocadağlı et al., studies on acrylamide mitigation in baked products

- Peer reviewed RF drying studies referenced in the white paper