RF Interference in Industrial RF Equipment: Why True CE Compliance Matters

Radio Frequency (RF) technology is widely used in industrial processing — from textile drying and post-baking to defrosting and disinfestation. While RF delivers clear process advantages, it also carries a critical responsibility: ensuring that RF energy does not interfere with surrounding communication systems.

This is where many RF machines fall short.

While most manufacturers rely on shielding or containment to limit RF leakage, Strayfield takes a fundamentally different approach by filtering interference at the source itself — before unwanted signals are ever generated or allowed to escape.

As a result, not all “CE-marked” RF machines are truly equal.

So, what does filtering at the source actually mean — and why does it matter for compliance, safety, and long-term operation?

Here’s how the difference is engineered.

What Is RF Interference — and Why Is It a Concern?

Industrial RF equipment intentionally generates high-power electromagnetic energy. If this energy is not properly controlled, unwanted emissions (harmonics) can spill into frequency bands reserved for other services such as:

- Mobile and data networks

- Aviation and navigation systems

- Emergency and safety communications

When emissions exceed permitted limits, they introduce noise and signal disruption, potentially affecting communications far beyond the factory boundary.

Regulatory authorities can trace such interference back to its source — and non-compliant equipment may be required to:

- Modify operation

- Reduce output

- Or be shut down entirely

This is why electromagnetic compatibility (EMC) compliance is not optional — it is fundamental.

The Regulatory Framework: EN 55011 and CE Marking

In Europe and many global markets, RF industrial equipment must comply with EN 55011 (aligned with CISPR 11), which defines:

- Permitted emission limits across frequency bands

- Measurement methods for radiated disturbances

- Controls on harmonic emissions outside designated ISM bands

Certain RF frequencies — 13.56 MHz, 27.12 MHz, and 40.68 MHz — are globally reserved for ISM (Industrial, Scientific and Medical) use.

The fundamental frequency is allowed, but harmonics above it are strictly limited

Importantly:

Meeting health and safety radiation limits does NOT automatically mean EN 55011 compliance.

This distinction is often overlooked.

The Real Issue: Harmonics, Not the Fundamental

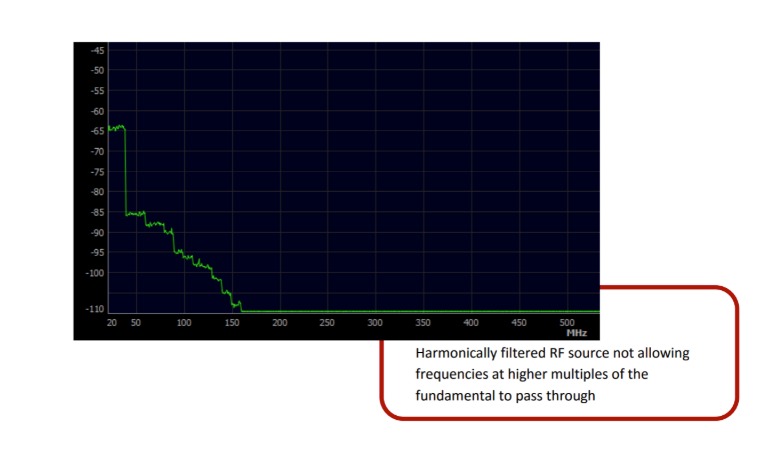

Every RF generator operates at a specific, permitted frequency — known as the fundamental frequency. However, as a natural result of RF generation, it also produces harmonics, which are unwanted frequencies at higher multiples of the fundamental.

These harmonics are the main cause of interference with nearby communication systems.

Many RF machine designs attempt to manage this problem by shielding the RF energy, essentially trying to stop it from leaking out of the machine. While shielding can help reduce overall emissions, it does not eliminate the harmonics themselves. The unwanted frequencies are still being generated — they are simply being contained or masked.

Some manufacturers go a step further by optimising test setups or operating conditions to meet compliance limits, without addressing the underlying source of interference.

Strayfield takes a fundamentally different approach.

Instead of trying to contain the problem, Strayfield machines eliminate it at the source by using an in-built PI harmonic filter within the RF generator. This filter blocks unwanted harmonics before they ever reach the applicator or escape the system.

This design-first approach is why engineering matters.

When harmonics are removed at the source, compliance is not dependent on shielding, test conditions, or workarounds — it is built into the machine itself.

What Is a PI Filter — and Why It Matters

A PI filter is a harmonic suppression network installed directly in the RF generator output stage. It is a built-in component inside Strayfield RF machines that helps keep radio signals clean and controlled.

In simple terms, it acts like a gatekeeper:

- It allows only the correct RF frequency needed for processing to pass through

- It blocks unwanted extra signals that can cause interference

Without proper filtering, an RF machine can give off multiple unwanted signals alongside the main one. These stray signals can interfere with nearby communication systems.

Strayfield machines come with in-built PI filters that remove these unwanted signals at the source, before they can escape the machine. The result is a much cleaner RF output that stays within permitted limits.

This means interference is prevented, not just reduced or hidden — ensuring reliable operation and true regulatory compliance.

Without PI filtering

With PI filtering

Independent Proof: Third-Party EMC Testing

Strayfield RF systems are not “self-declared compliant” — they are independently tested in real operating conditions.

A third-party EMC test evaluated a Strayfield 2 × 40 kW RF Textile Dryer against the requirements of IEC CISPR 11:2019.

Key findings:

- Complies as a Class A Group 2 ISM device

- Radiated emissions from 15–30 MHz and 30–1000 MHz fully compliant

- No spurious emissions detected outside permitted ISM bands

- Tested in situ, not under artificial laboratory conditions

Image: Outdoor in-situ radiated emission measurements performed around a Strayfield RF installation, as part of real-world EMC compliance testing.

The system operated at 27.12 MHz, with harmonics controlled well below regulatory limits — confirming the effectiveness of Strayfield’s harmonic suppression design.

CE Compliance Done Right

CE compliance is not just a label — it is a legal and technical obligation.

In the case of RF machines, there is a specific and critical requirement that is often overlooked:

the machine must not interfere with other communication systems.

While many RF equipment suppliers claim CE compliance, this requirement related to electromagnetic interference (EMC) is frequently addressed superficially — or ignored altogether.

True CE compliance for RF equipment means:

- Designing for electromagnetic compatibility (EMC) from the outset

- Controlling harmful harmonics at the source, not just reducing emissions externally

- Testing under real-world operating conditions

- Meeting both safety and interference regulations, including EN 55011 / CISPR 11

Strayfield RF machines are engineered specifically to meet this often-overlooked requirement. They incorporate:

- In-built, purpose-designed PI harmonic filters

- Full compliance with EN 55011 / CISPR 11

- Verified third-party EMC test results carried out in real operating environments

As a result, Strayfield machines go beyond checkbox compliance — delivering true CE compliance for RF equipment, with no risk of communication interference, regulatory action, or operational disruption.

Final Thoughts

RF interference is rarely noticed — until it becomes a problem.

By the time communication systems are affected or authorities get involved, the cost of “assumed compliance” becomes very real.

In RF processing, CE marking alone is not enough. What matters is how that compliance is achieved:

- Are harmonics eliminated at the source?

- Is EMC compliance engineered into the machine, or managed around it?

- Has the equipment been proven under real-world conditions — not just in a test environment?

In RF systems, shortcuts eventually show.

Only compliance that is designed, tested, and proven stands up over time.