Meat Defrosting Machines: Revolutionizing Food Processing with Radio Frequency Heaters for Defrosting, Tempering, and Heating

The Importance of a Meat Defrosting/Thawing Machine and Food Tempering

In the food processing industry, rapid defrosting has become an essential process to reduce the time between the freezing and the further processing of food products. Rapid defrosting allows for the quick and safe thawing of frozen food, saving time and reducing the risk of spoilage. The quicker and more efficient the process, the better the results. Strayfield’s Radio Frequency (RF) heaters are a game-changer in the world of rapid tempering/defrosting or thawing of meat, seafood & fruit pulps.

How Defrosting Machines Work and Their Advantages Over Traditional Defrosting Methods

Strayfield RF defrosting machines use electromagnetic energy to heat food directly (as opposed to convective heating). This is faster and more efficient than traditional methods. Our machines can defrost meat up to 50 times faster than traditional defrosting methods, making it an ideal meat thawer. Our RF meat defrosting machines are gentler on the food product, preserving the quality of the meat.

Benefits of Strayfield’s rapid defrosting for the food industry

Increased Efficiency

Rapid defrosting reduces the time it takes to thaw food products, allowing for faster production and increased efficiency. This is especially important for businesses that need optimal or maximum production or processing capacity.

Improved Quality

Reduced Waste

Rapid defrosting helps to reduce the amount of waste generated by the food industry. By quickly thawing food products, businesses can reduce the risk of bacterial growth and extend the life of their products.

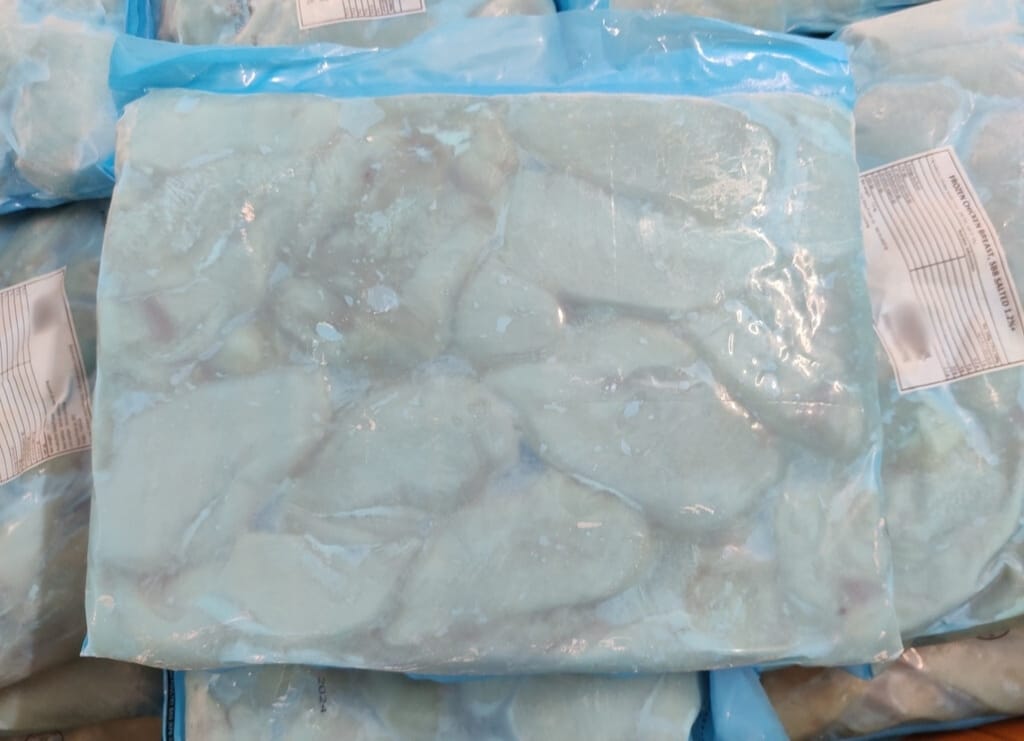

Defrosting Fish and Seafood with Strayfield

RF Heaters: Efficiency and Preservation of Texture

Strayfield RF heaters can also be used for defrosting fish and other seafood; a process that can be challenging due to the delicate nature of the product. Our RF heaters defrost fish quickly and efficiently while maintaining the texture and quality of the fish.

Technology Advantages

- RF technology enables continuous flow lines, allowing for high productivity rates. Unlike traditional methods that require batch processing or individual handling, Strayfield’s RF tempering machines can be integrated into automated production lines, ensuring a continuous and efficient thawing process. This eliminates downtime between batches, resulting in increased overall productivity.

- Uniform thawing is crucial to minimize drip losses in the defrosting process. RF technology provides a consistent and controlled heating environment, ensuring an even thawing rate across the entire product. This uniformity helps to preserve the quality and integrity of the food, reducing the loss of valuable juices and moisture.

- Short processing times are advantageous in minimizing the growth of microbes during thawing. RF technology offers rapid and precise heating capabilities, allowing for extremely short processing times. The quick and efficient thawing process limits the exposure of the product to temperatures that promote microbial growth, effectively reducing the risk of bacterial contamination.

- RF systems can be designed to occupy a relatively smaller footprint compared to traditional thawing methods. This reduction in floor space requirement is beneficial for food processing facilities where space optimization is crucial. By utilizing RF technology, companies can make the most efficient use of their available floor area, optimizing their overall operational efficiency.

Strayfield Advantages

- Energy efficiency: Highest energy efficiency in the industry

- Filtered Oscillator design: Strayfield is the only manufacturer with a filtered oscillator design that adheres to EN55011 and is truly CE compliant

- Double electrode balanced output: Isolated energy in the area of application that minimises the return current paths through the structure of the machine, thereby reducing RF emissions and improving efficiency.

- Automatically adjusting electrodes that ensure controlled power and unmatched arc suppression

- Flat electrodes: Lower power density as opposed to rod electrodes, ensuring uniform and gentle thawing.

- Dual Extraction Design

Differences between RF and Microwave Technologies

RF technology uses high-frequency electromagnetic fields to heat and thaw materials. The energy penetrates the material and generates heat through the friction created by the movement of water molecules.

Microwave technology uses ultrahigh frequency traveling electromagnetic waves (as opposed to electric fields in RF technology) to heat and thaw materials. The energy is absorbed by the material, causing the molecules within it to vibrate and generate heat. Microwave technology is commonly used in household appliances, such as microwave ovens, and is suitable for small-scale production due to the large variations that can occur at high volumes.

Put simply, RF technology uses lower frequencies over microwave technologies. This allows RF energy to penetrate deeper into the material and generate heat more homogeneously. The following are key advantages of RF vs Microwave in industrial tempering:

Efficiency

RF technology is more efficient than microwave technology at large volumes from an investment & productivity standpoint. This is due to the homogenous nature of the final product and the ability to significantly reduce waste.

Capacity

RF technology is suitable for large-scale production, while microwave technology is better suited for small-scale applications. This is because, RF energy has the capability to penetrate large volumes of mass evenly/uniformly as opposed to microwaves, by a factor of 10.

Dielectric properties

Food ingredients (especially ice) are transparent to microwave energy at low temperatures thus resulting in extremely inefficient heating of deep-frozen material.

A case study on RF tempering using Strayfield

Discover how our RF defrosting technology is setting new standards in the food industry. Dive into our case study on butter defrosting to see how our units ensure rapid and consistent tempering without compromising quality.

Tempering Lines For

Frozen Vegetables

Surimi

Pork Belly

Beef

Whole Fish

Chicken

Fruit Pulps