RF Drying machines by Strayfield are the industry norm for the best quality textile packages and loose fibers

RF (Radio Frequency) drying has revolutionized the textile drying industry by offering numerous advantages over traditional drying methods. With its precise control, speed, and efficiency, RF drying has transformed the way textiles are dried, resulting in improved quality, increased productivity, and reduced environmental impact.

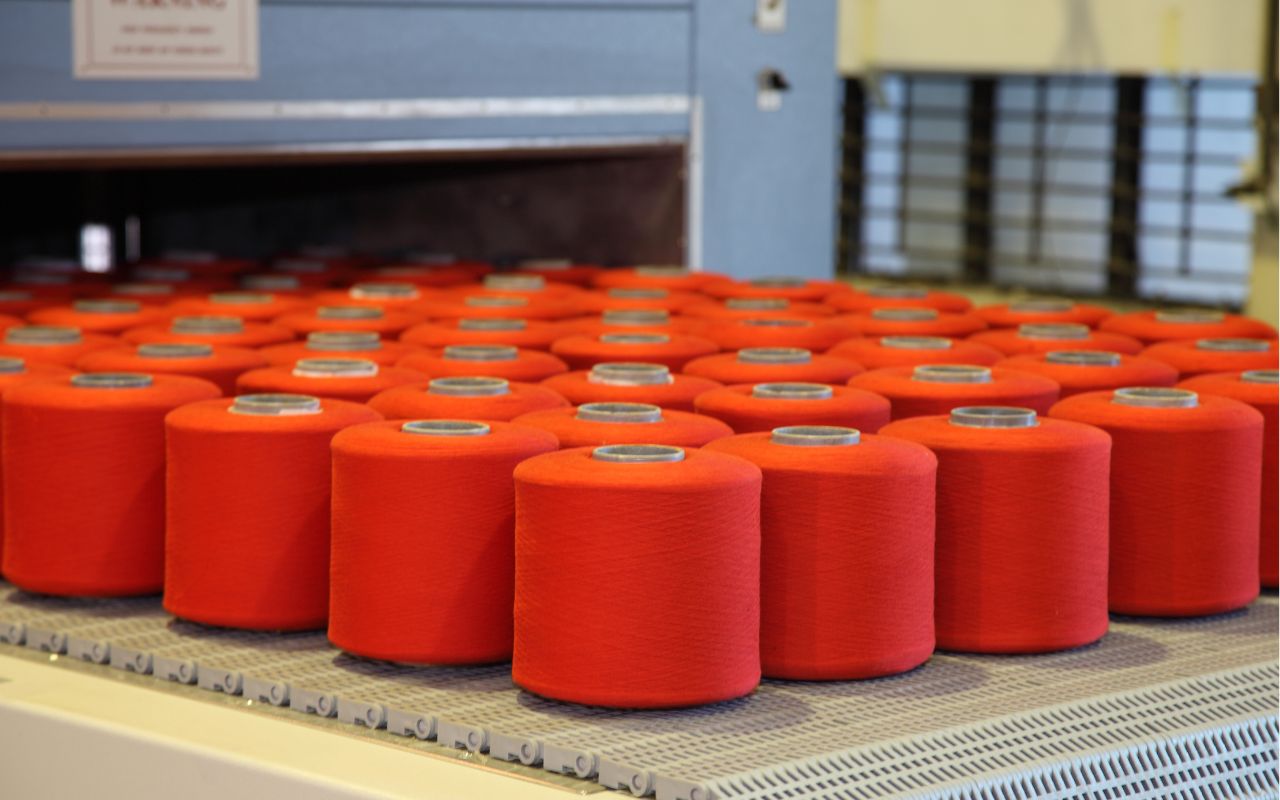

One of the major benefits of RF drying for the textile industry is its ability to uniformly dry textiles while maintaining yarn integrity and strength. Yarns and fibers, presented in formats such as packages, bobbins, spools, hanks, or fabric rolls, can be efficiently dried using RF technology. Unlike traditional drying methods that can lead to uneven drying and damage, RF technology ensures consistent and controlled drying, preserving the structural integrity of the yarn or fabric.

RF drying also eliminates dye migration and prevents yellowing of textiles. By reducing drying time and minimizing exposure to high temperatures, RF technology eliminates the risk of dyes bleeding into adjacent areas and helps retain the vibrant colors of textiles. This ensures that the textiles remain visually appealing and free from discoloration.

RF drying has been successfully applied to various types of textile forms. Whether it’s fabrics, yarns, fibers, or non-woven mats, RF technology offers versatility across a wide range of materials. This adaptability makes RF drying a valuable solution for different textile manufacturing processes.

From spinning and weaving to knitting and finishing, RF drying has found applications throughout the textile industry. By reducing drying time and enhancing efficiency, RF technology significantly increases productivity in these processes. Additionally, RF drying can add volume and thickness to yarns, contributing to enhanced yarn bulking, which is particularly advantageous for specific applications.

Advantages of Strayfield RF for yarn drying applications

Dive deeper into our RF drying technology on our blog: Learn how our Radio Frequency equipment is minimising drying costs for textile yarn packages.

Technology Advantages

- Uniformly dries product maintaining yarn integrity and strength: RF technology enables precise control over the drying process, ensuring that textiles are dried evenly. This helps preserve the integrity and strength of the yarn or fabric, preventing uneven shrinkage or damage commonly seen with traditional drying methods.

- Mitigates dye migration and yellowing: RF drying minimizes the risk of dye migration, where dyes bleed into adjacent areas during drying. By reducing drying time, RF technology decreases the likelihood of color migration. Additionally, it avoids prolonged exposure to high temperatures, which can cause yellowing of textiles.

- Increases productivity significantly: RF drying is highly efficient and quick. It reduces drying time compared to conventional methods like hot air or steam drying. The increased speed translates to higher productivity, allowing textile manufacturers to process more products within a shorter timeframe.

- Avoids fungal damage by eliminating wet spots: Traditional drying methods often result in uneven drying, leaving wet spots or areas with retained moisture. These wet spots can foster fungal and bacterial growth, leading to textile damage. RF drying eliminates wet spots, reducing the risk of fungal damage.

- Enhances yarn bulking: RF technology can enhance yarn bulking, particularly in certain textile types. Controlled heating in RF drying causes fibers to expand, resulting in increased volume and bulkiness. This effect is beneficial for textiles requiring specific loft or thickness.

- Energy-efficient and reduces environmental impact: RF drying systems are generally energy-efficient compared to conventional methods. By directly heating water molecules within textiles, RF technology minimizes heat loss to the surrounding environment. This energy efficiency leads to cost savings and reduced environmental impact.

- Reduces fabric distortion: RF drying minimizes fabric distortion such as puckering or wrinkling, common in conventional drying methods. The controlled and even distribution of heat helps maintain the fabric’s original shape and dimensions, resulting in a more uniform end product.

- Versatile for different textile types: RF drying technology in the textile industry is adaptable to a wide range of textile materials, including natural and synthetic fibers. This versatility makes it suitable for various textile manufacturing processes.

- Improves process control and automation: RF drying systems can be integrated into automated production lines, offering better process control and monitoring. Precise control over temperature, moisture content, and drying time ensures consistent and reproducible drying results.

- Lowers carbon footprint: RF drying systems contribute to a reduced carbon footprint. Energy efficiency and faster drying times decrease energy consumption, while reduced chemical and water usage in some cases make RF technology environmentally friendly compared to conventional drying methods.

Strayfield Advantages

- Energy efficiency: Highest energy efficiency in the industry

- Filtered Oscillator design: Strayfield is the only manufacturer with a filtered oscillator design that adheres to EN55011 and is truly CE compliant

- Double electrode balanced output: Isolated energy in the area of application that minimises the return current paths through the structure of the machine, thereby reducing RF emissions and improving efficiency.

- Automatically adjusting electrodes that ensure controlled power and unmatched arc suppression

- Flat electrodes: Lower power density as opposed to rod electrodes, ensuring uniform and gentle heating & drying

- Dual Extraction Design

Unveiling the Potential of Banana Fibre

Explore the innovative use of banana fibre in the textile industry on our blog. Understand its environmental impact and how RF drying technology can enhance its application in modern textiles.

Dryers For

Yarn Packages

Hanks

Loose Fibers

Non woven fabric

Ropes and Tow forms

Tops

Towels and bathmats

Synthetic yarn and fabric

FAQs for our RF dryers

RF Dryers offer several key advantages:

Enhanced Efficiency: They provide faster drying and production, which can increase labor productivity.

Energy Savings: The technology is designed for high energy transfer efficiency, leading to significant energy savings.

Uniform Drying: RF Dryers ensure uniform heating within the product, leading to consistent drying.

Space Efficiency: These dryers generally occupy less space compared to traditional drying methods.

Reduced Maintenance and Downtime: Strayfield’s dryers require lower maintenance and have less downtime.

The technology is known for its gentle drying process, which preserves the quality of textiles. It minimizes the risk of uneven shrinkage and overdrying and maintains the sensorial, chemical, and physical characteristics of the product.

Yes, RF Dryers are suitable for drying most types of fibres, including acrylic, cotton, nylon, and polyester blends, in various forms like a cone, muff, bump, or loose stock